MP-H series high temperature and high pressure melt pump

Product Introduction

MP-H series high temperature and high pressure melt pump is suitable for engineering plastics, film blowing and other processes.

The main features of H series melt gear pump

1, can be applied to high temperature (<510℃) high pressure (<70MPa) high viscosity (<20,000Pa•s) working conditions;

2, the optimal design of inlet and outlet, to avoid the dead Angle in the flow channel to the maximum extent, reduce material residues, improve product quality.

3, improved gear parameter design, can withstand ultra-high pressure and greater pressure difference.

4, using special materials, high temperature resistance, long service life.

5. Adopt high precision mechanical seal.

6, according to the customer's different site conditions to provide the appropriate installation method, more flexible and practical.

Technical parameter

Viscosity: ≤20000Pa.s

Operating temperature: ≤510℃

Cleaning temperature: ≤590℃

Outlet pressure: ≤70Mpa

Pressure difference up to 50Mpa

Main structure

Pump body: CPM tool steel, titanium bile alloy

Gear: CPM tool steel, titanium bile alloy, special materials and wear resistant coating

Plain bearings: CPM tool steel, titanium bile alloy, special materials and wear resistant coating

Shaft seal: screw mechanical seal

Specifications/Flow range: 5CC-2500CC

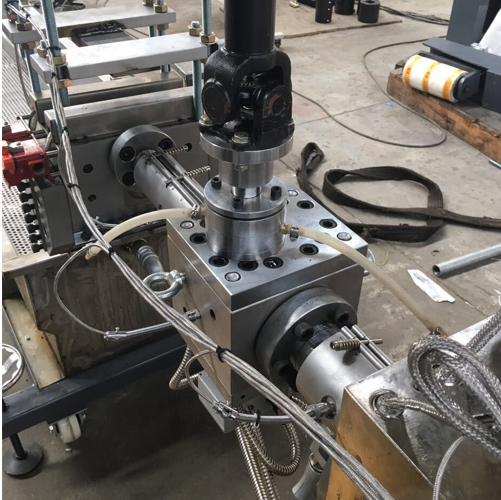

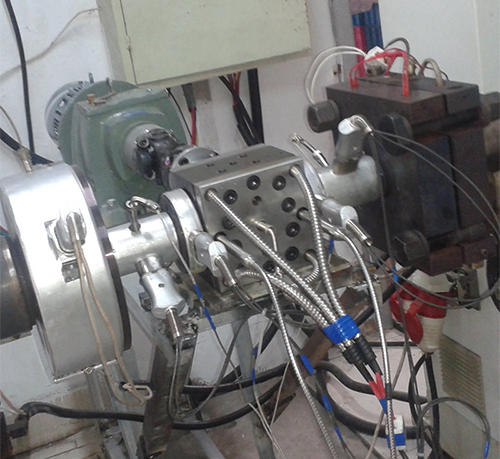

Melt pump application case

Installation mode

The H series melt pump can be installed in a variety of ways, and the input shaft of the pump can be arranged horizontally or vertically (up and down); The drive system generally includes: motor, reducer, universal coupling, pump connector, reducer connection, etc.;

The complete set of equipment includes melt pump, inlet and outlet adaptor, drive system, control system, etc. Customers can choose according to the specific situation

| Model | Special Volume cc/r |

Inlet pressure MPa |

Outlet pressure MPa |

Service temperature °C | Recommended Capacity L/h | ||

| <200Pa.s | 200-2000Pa.s | >2000Pa.s | |||||

| MP-H-5CC | 5 | 0-35 | ≤70 | ≤450 | 30 | 24 | 18 |

| MP-H-10CC | 10 | 60 | 48 | 36 | |||

| MP-H-20CC | 20 | 120 | 96 | 72 | |||

| MP-H-31.5CC | 32 | 189 | 151.2 | 113.4 | |||

| MP-H-50CC | 50 | 300 | 240 | 180 | |||

| MP-H-100CC | 100 | 480 | 360 | 300 | |||

| MP-H-150CC | 150 | 720 | 540 | 450 | |||

| MP-H-200CC | 200 | 960 | 720 | 600 | |||

| MP-H-250CC | 250 | 900 | 750 | 600 | |||

| MP-H-315CC | 315 | 1134 | 945 | 756 | |||

| MP-H-500CC | 500 | 1800 | 1500 | 1200 | |||

| MP-H-800CC | 800 | 2880 | 2400 | 1920 | |||

| MP-H-1000CC | 1000 | 3000 | 2400 | 2400 | |||

| MP-H-1200CC | 1200 | 3600 | 2880 | 2880 | |||

Note:

The output of melt gear pump is related to material viscosity, temperature, working pressure and speed, please consult the manufacturer for specific selection.

Previous:MP-X rubber gear pump

Next: MP-R series reactor melt pump