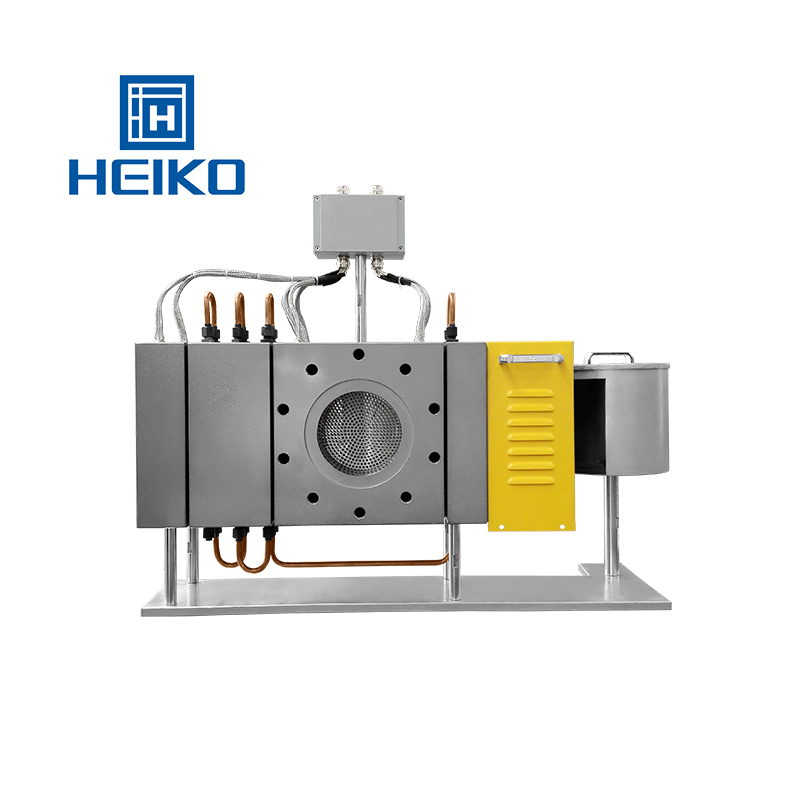

Automatic mesh belt continuous screen changer

Performance characteristics

Mesh belt melt filter automatic mesh changer is an automatic mesh changer in the true sense, using melt pressure or time to control the action of the mesh changer. The distance and speed of the filter can be freely set. When the pressure or time reaches the set value, the filter automatically moves evenly, and the impurities are brought out of the screen changer with the filter. After setting, the mesh changer is fully automated without manual operation, the mesh belt moves gently, the distance is small, the material pressure and the material flow are not fluctuating, and the constant pressure production is truly realized. The mesh belt type mesh changer adopts water-cooled seal, no leakage, no wear, automatically controlled by the control system heating and cooling, and the filter is flexible. The product does not deform in the process of changing the mesh, and the quality stability is good. No waste, waste generation, low consumption of raw materials and other characteristics are widely used in the production of high-quality, long flow or short range products such as granulation, casting film, sheet, plate, optical fiber, and various kinds of wire drawing. It is especially suitable for the production of high-precision products which require strict material pressure fluctuation.

Scope of application

1. There is no fluctuation of pressure during the filter change process, which has no impact on product quality.

2. Self-sealing, never leakage.

3. Automatic mesh change, no manual operation.

4. Small space, novel structure, easy to install.

5. No wear and tear, long service life.

6. Removable movable filter block (porous plate), easy maintenance and cleaning.

Technical parameter

| Type | Capacity (kg/h) | Dimension (mm) | Screen size | Heater | ||||

| typc | kg/h | L1 | L2 | L3 | Diameter (mm) | Area (cm2) | Voltage (v) | Power (w) |

| HK-ACB-50 | 30~85 | 150 | 165 | 540 | Φ50 | 20 | 230/400 | 5200 |

| HK-ACB-70 | 75~200 | 160 | 170 | 560 | Φ70 | 38 | 230/400 | 5400 |

| HK-ACB-90 | 100~290 | 170 | 185 | 580 | Φ90 | 64 | 230/400 | 5800 |

| HK-ACB-100 | 130~350 | 180 | 215 | 605 | Φ100 | 78 | 230/400 | 6200 |

| HK-ACB-120 | 190~500 | 185 | 230 | 640 | Φ120 | 113 | 230/400 | 6500 |

| HK-ACB-150 | 350~800 | 200 | 265 | 700 | Φ150 | 176 | 230/400 | 7200 |

| HK-ACB-180 | 450~1200 | 220 | 305 | 760 | Φ180 | 254 | 230/400 | 8200 |

The actual yield depends on the flow of the material, the filtration accuracy and the purity of the material. Parameters are subject to change without prior notice!

Heiko screen changer manufacturers

Zhengzhou Heiko is specialized in the production and sales of melt pumps, high temperature melt extrusion pumps, mesh changers, high precision filters and precision control systems (PLC) and other products. It is one of the earliest enterprises specializing in the production of melt gear pump and mesh changer in China. The company independently develops and produces MP-S, MP-M, MP-H, MP-C and other series of high temperature melt gear pump products and HK-ACB, HK-SSP, HK-FSP, HK-DP and other series of mesh changer products. Nowadays, mesh changers and melt gear pumps have been widely used in chemical fiber, granulation, plastic film, sheet, plate, profile, pipe, wire and cable, wire drawing, composite extrusion and other production lines, and the materials that can be processed almost cover most of the polymer materials, such as: PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymer, polysulfone, polyester, thermoplastic elastomer, rubber and thermal adhesive, etc.

The company integrates scientific research and production, and is committed to the development and promotion of melt gear pump and screen changer products. The company draws on the advanced technical experience of the same industry at home and abroad, and strives to create a professional melt pump manufacturer with the best products, the lowest price and the best service.

Previous:返回列表

Next:Double column large filter cartridge type screen changer