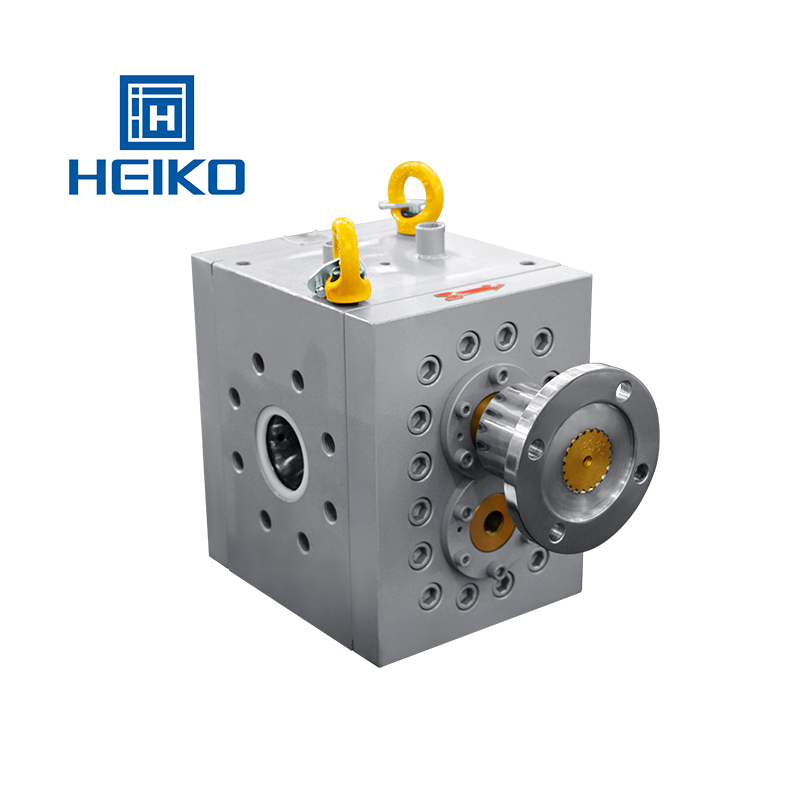

MP-X rubber gear pump

Product introduction

Rubber pump for elastomer and easily degradable plastic extrusion system, this type of pump is with a special internal structure, with efficient self-cleaning function, suitable for the extrusion of compounding generally installed in the extruder outlet and die for pressurizing and metering.

Main application range

PVC, BR, CR, EPDM, NBR, SBR, natural rubber, other degradable materials.

Main features:

1) Can be applied to high pressure (40MPa), high viscosity (40,000Pa·s) working conditions;

2) High finish, almost mirror, suitable for heat-sensitive materials;

3) Precise structure, high temperature control accuracy.

4) Optimize the flow path and lubrication system, with efficient self-cleaning function, no residual materials, no dead corners.

Technical parameters

Viscosity of conveying medium: 1 ~ 40000Pa·s (1,000 ~ 40,000,000cP)

Inlet pressure: 0 ~ 30MPa

Outlet pressure: 0 ~ 40MPa

Pressure difference up to 25MPa

Operating temperature: ≤350℃

Main structure

Pump body: nitriding steel tool steel inner flow channel for mirror treatment

Gear: Tooth shape straight teeth or helical teeth tool steel/special alloy for mirror finish

Shaft sleeve: tool steel/special alloy

Heating method: circulating water heating

Cooling method: shaft end cooling system

Shaft: Double shaft drive with water cooling

Shaft seal: spiral discharge outer

Specifications/Flow range: 31.5CC-800CC

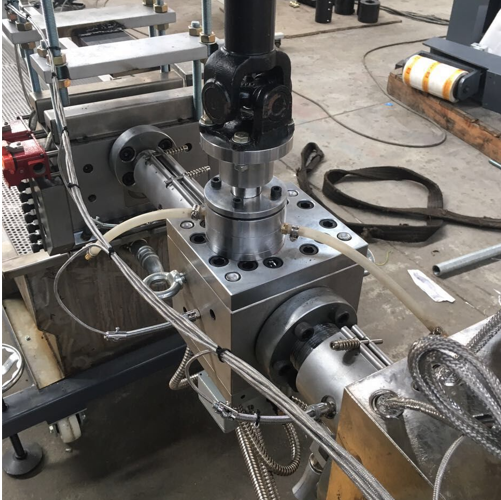

Melt pump application case

Installation mode

The X series melt pump can be installed in a variety of ways, and the input shaft of the pump can be arranged horizontally or vertically (up and down); The drive system generally includes: motor, reducer, universal coupling, pump connector, reducer connection, etc.;

The complete set of equipment includes melt pump, inlet and outlet connection, drive system, control system, etc. Customers can choose according to the specific situation

| Model number | Rotational capacity cc/r |

Inlet pressure MPa |

Outlet pressure MPa |

Service temperature °C | Recommended traffic L/h | ||

| Medium and low viscosity materials | Medium and high viscosity material | Ultra-high viscosity material | |||||

| <200Pa.s | 200-2000Pa.s | >2000Pa.s | |||||

| MP-X-5CC | 5 | 0-35 | ≤40 | <350 | 27 | 18 | 12 |

| MP-X-10CC | 10 | 54 | 36 | 24 | |||

| MP-X-20CC | 20 | 108 | 72 | 48 | |||

| MP-X-31.5CC | 31.5 | 170 | 113.4 | 75.6 | |||

| MP-X-50CC | 50 | 270 | 180 | 120 | |||

| MP-X-100CC | 100 | 480 | 324 | 120 | |||

| MP-X-150CC | 150 | 720 | 486 | 180 | |||

| MP-X-200CC | 200 | 960 | 648 | 240 | |||

| MP-X-250CC | 250 | 1050 | 675 | 450 | |||

| MP-X-315CC | 355 | 1323 | 756 | 567 | |||

| MP-X-500CC | 500 | 2100 | 1200 | 900 | |||

| MP-X-800CC | 800 | 3360 | 1920 | 1440 | |||

Specify

1. The output of melt gear pump is related to material viscosity, temperature, working pressure and speed, please consult the manufacturer for specific selection.

2. Pump selection needs to provide: pump front equipment name, output, material type, whether corrosive (and special characteristics), working temperature, viscosity, import and export pressure value.

3. Please contact the manufacturer for special customization requirements.

4. Consult the manufacturer if the export is greater than 40MPa.

Previous:MP-C series transparent material melt pump

Next:MP-H series high temperature and high pressure melt pump