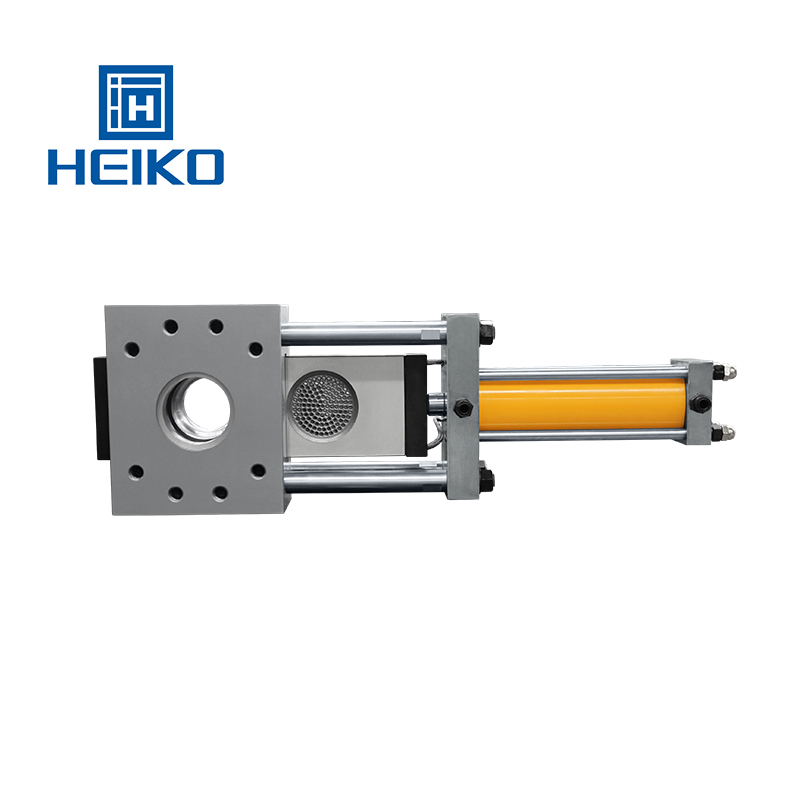

Single plate double screen cavities screen changer (square)

Performance characteristics

Single plate double screen cavities screen changer is a cost-effective, excellent performance screen changer. It can quickly switch the filter in 0.4 seconds, fast mesh change, small changes in material flow, no leakage, high pressure resistance, large filter area, simple operation, fast mesh change, high wear resistance, high pressure resistance, high precision filter design, improve the effective area and filter quality. Under the condition of temperature of about 300℃, it does not affect the performance of use, and can achieve rapid network change without stopping. Indispensable supporting equipment in plastic sheet, sheet, film, pipe, granulation and other extrusion production lines. Common configuration: net changer body (including cylinder, heating tube) + hydraulic station + electric control box (optional).

Scope of application

Single plate double screen cavities screen changer is mainly used in the following production lines:1. Granulation production line (PP, PE, PET, PA and other polymer materials)

2. Film production line (PET CPE BOPP PE HDPE and other materials)

3. Sheet and plate production line (PP PE PET ABS and other materials)

4. Packaging belt production line (PP PET material)

5. Production of hollow products

Application case

Technical parameter

| Type | Capacity (kg/h) | Dimension (mm) | Screen size | Heater | |||||

| L1 | L2 | L3 | L4 | Diameter (mm) | Area (cm2) | Voltage (v) | Power (w) | ||

| HK-SSP-A-70 | 75~200 | 100 | 715 | 170 | 240 | Φ70 | 38 | 230/400 | 3500/5800 |

| HK-SSP-A-100 | 130~350 | 110 | 815 | 185 | 280 | Φ100 | 78 | 230/400 | 4500/6800 |

| HK-SSP-A-120 | 200~550 | 130 | 880 | 205 | 320 | Φ120 | 113 | 230/400 | 5200/7200 |

| HK-SSP-A-150 | 350~800 | 150 | 995 | 235 | 360 | Φ150 | 176 | 230/400 | 6500/8500 |

| HK-SSP-A-180 | 450~1250 | 160 | 1120 | 245 | 360 | Φ180 | 254 | 230/400 | 7600/9500 |

| HK-SSP-A-200 | 550~1500 | 180 | 1255 | 280 | 420 | Φ200 | 314 | 230/400 | 8500/11000 |

| HK-SSP-A-250 | 800~2500 | 225 | 1325 | 300 | 430 | Φ250 | 490 | 230/400 | 9500/12000 |

| HK-SSP-A-300 | 1200~3500 | 260 | 1470 | 380 | 500 | Φ300 | 706 | 230/400 | 11500/15500 |

| HK-SSP-A-320 | 1500~4000 | 300 | 1660 | 400 | 560 | Φ320 | 803 | 230/400 | 13000/17500 |

The actual yield depends on the flow of the material, the filtration accuracy and the purity of the material. Parameters are subject to change without prior notice!

Heiko screen changer manufacturers

Zhengzhou Heiko is specialized in the production and sales of melt pumps, high temperature melt extrusion pumps, mesh changers, high precision filters and precision control systems (PLC) and other products. It is one of the earliest enterprises specializing in the production of melt gear pump and net changer in China. The company independently develops and produces MP-S, MP-M, MP-H, MP-C and other series of high temperature melt gear pump products and HK-ACB, HK-SSP, HK-FSP, HK-DP and other series of net changer products. Nowadays, mesh changers and melt gear pumps have been widely used in chemical fiber, granulation, plastic film, sheet, plate, profile, pipe, wire and cable, wire drawing, composite extrusion and other production lines, and the materials that can be processed almost cover most of the polymer materials, such as: PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymer, polysulfone, polyester, thermoplastic elastomer, rubber and thermal adhesive, etc.

The company integrates scientific research and production, and is committed to the development and promotion of melt gear pump and screen changer products. The company draws on the advanced technical experience of the same industry at home and abroad, and strives to create a professional melt pump manufacturer with the best products, the lowest price and the best service.

Previous:Single plate hydraulic screen changer with four working station

Next:Single plate double screen cavities screen changer (round)