MP-C series transparent material melt pump

Product Introduction

The MP-C series transparent material melt pump is mainly used for the smooth pressurization of medium and high viscosity media in the polymer flow layer. Suitable for PS, PP, PVC, PC, PMMA, EVA and other transparent materials or heat sensitive material process.

The main features of C series melt gear pump

1, can be applied to high temperature (350℃) high pressure (35MPa) high viscosity (20,000Pa·s) working conditions;

2, the import and export horn design, to avoid the dead Angle in the flow channel to the maximum extent, reduce material residues, improve product quality.

3, improved gear parameter design, so that the output pressure is more stable, reduce temperature rise, suitable for precision extrusion.

4, the use of special materials and wear-resistant coating, high finish, good wear resistance, long life.

5. Adopt high precision mechanical seal.

6, according to the customer's different site conditions to provide the appropriate installation method, more flexible and practical.

Technical parameter

Transport medium viscosity: 200 ~ 20000Pa•s (2,000 ~ 20,000,000cP)

Inlet pressure 0 ~ 30MPa

Outlet pressure 0 ~ 40MPa

The pressure difference can reach 25MPa

Operating temperature ≤350℃

Main structure

Pump body: high temperature alloy steel, chrome-nickel alloy steel, titanium bile alloy

Gear: special material and wear-resistant coating, tooth shape is straight, helical or herringbone teeth

Plain bearings: high temperature tool steel, special materials and wear resistant coating

Shaft seal: screw mechanical seal

Heating method: electric heating

Specifications/Flow range: 10CC-3200CC

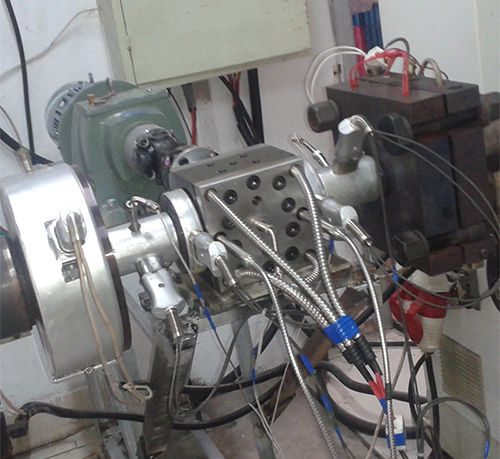

Melt pump application case

Installation mode

The C series melt pump can be installed in a variety of ways, and the input shaft of the pump can be arranged horizontally or vertically (up and down); The drive system generally includes: motor, reducer, universal coupling, pump connector, reducer connection, etc.;

The complete set of equipment includes melt pump, inlet and outlet connection, drive system, control system, etc. Customers can choose according to the specific situation

| Model number | Rotational capacity cc/r |

Inlet pressure MPa |

Outlet pressure MPa |

Service temperature °C | Recommended traffic L/h | ||

| Medium and low viscosity materials | Medium and high viscosity material | Ultra-high viscosity material | |||||

| <200Pa.s | 200-2000Pa.s | >2000Pa.s | |||||

| MP-C-0.6CC | 0.6 | 0-35 | ≤45 | <350 | 3.6 |

2.4 |

1.8 |

| MP-C-1CC | 1 | 6 | 4 | 3 | |||

| MP-C-2CC | 2 | 10.8 | 8.04 | 4.92 | |||

| MP-C-5CC | 5 | 27 | 18.9 | 12 | |||

| MP-C-10CC | 10 | 54 | 37.8 | 24 | |||

| MP-C-20CC | 20 | 108 | 75.6 | 48 | |||

| MP-C-31.5CC | 31.5 | 170 | 119.1 | 75.6 | |||

| MP-C-50CC | 50 | 270 | 162 | 120 | |||

| MP-C-100CC | 100 | 480 | 324 | 216 | |||

| MP-C-150CC | 150 | 720 | 486 | 324 | |||

| MP-C-200CC | 200 | 960 | 648 | 432 | |||

| MP-C-250CC | 250 | 1050 | 675 | 465 | |||

| MP-C-315CC | 315 | 1323 | 756 | 586 | |||

| MP-C-500CC | 500 | 2100 | 1200 | 900 | |||

| MP-C-800CC | 800 | 3360 | 1920 | 1488 | |||

| MP-C-1000CC | 1000 | 3600 | 2160 | 1860 | |||

| MP-C-1200CC | 1200 | 4320 | 2592 | 2232 | |||

| MP-C-1600CC | 1600 | 5760 | 3456 | 2976 | |||

| MP-C-2000CC | 2000 | 7200 | 4320 | 3720 | |||

| MP-C-2500CC | 2500 | 7500 | 4650 | 4050 | |||

| MP-C-3200CC | 3200 | 9600 | 5952 | 5184 | |||

| MP-C-4000CC | 4000 | 10800 | 7440 | 6480 | |||

| MP-C-6300CC | 6300 | 17010 | 1020.6 | 9072 | |||

| MP-C-8000CC | 8000 | 17280 | 1296 | 1152 | |||

indicate

1. The output of melt gear pump is related to material viscosity, temperature, working pressure and speed, please consult the manufacturer for specific selection.

2. Pump selection needs to provide: pump front equipment name, output, material type, whether corrosive (and special characteristics), working temperature, viscosity, import and export pressure value.

3. Please contact the manufacturer for special customization requirements.

Zhengzhou Heiko melt pump manufacturers

Zhengzhou Heiko is specialized in the production and sales of melt pumps, high temperature melt extrusion pumps, mesh changers, high precision filters and precision control systems (PLC) and other products. It is one of the earliest enterprises specializing in the production of melt gear pump and net changer in China. The company independently develops and produces MP-S, MP-M, MP-H, MP-C and other series of high temperature melt gear pump products and HK-ACB, HK-SSP, HK-FSP, HK-DP and other series of net changer products. Nowadays, mesh changers and melt gear pumps have been widely used in chemical fiber, granulation, plastic film, sheet, plate, profile, pipe, wire and cable, wire drawing, composite extrusion and other production lines, and the materials that can be processed almost cover most of the polymer materials, such as: PE, PC, PP, PVC, HIPS, PS, PA, TPUR, fluoropolymer, polysulfone, polyester, thermoplastic elastomer, rubber and thermal adhesive, etc.

The company integrates scientific research and production, and is committed to the development and promotion of melt gear pump and screen changer products. The company draws on the advanced technical experience of the same industry at home and abroad, and strives to create a professional melt pump manufacturer with the best products, the lowest price and the best service.

Previous:MP-M Melt Pump for Plastic Extrusion

Next:MP-X rubber gear pump