What specific materials are suitable for wood-plastic composite melt pumps?

Wood-plastic composite melt pumps are primarily suitable for the following specific materials:

I. Main Raw Materials

Thermoplastic Plastics

These include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and their copolymers, among others. These materials serve as adhesives, connecting and reinforcing the wood flour filler in wood-plastic composites.

Wood Flour

Materials such as wood, agricultural plant straws, and agricultural plant shell powders. These serve as fillers, providing the natural texture and strength of wood-plastic composites.

II. Additives

Plasticizers

Such as dibutyl phthalate (DBP), used to improve the flexibility and processability of wood-plastic composites.

Light Stabilizers and UV Absorbers

For instance, hindered amine light stabilizers, used to enhance the light aging resistance of wood-plastic composites.

Antibacterial Agents

These maintain the hygienic properties and extend the service life of wood-plastic composites. The selection of antibacterial agents needs to consider factors such as the type of wood flour, additive amount, types of bacteria in the composite's use environment, and the product's moisture content.

Powdered Nitrile Rubber

It significantly improves the abrasion resistance, high and low temperature resistance of wood-plastic composites, extending their service life.

III. Characteristics of Suitable Materials

The materials suitable for wood-plastic composite melt pumps typically have the following characteristics:

High Viscosity: Wood-plastic composites have high viscosity in the molten state, requiring the melt pump to have strong conveying capabilities.

High Temperature Stability: The melt pump needs to operate stably at high temperatures, ensuring continuous material conveying and extrusion.

Abrasion Resistance and Corrosion Resistance: Due to the potential presence of wooden fibers and additives in the material, the melt pump needs to possess good abrasion and corrosion resistance to extend its service life.

IV. Application Examples

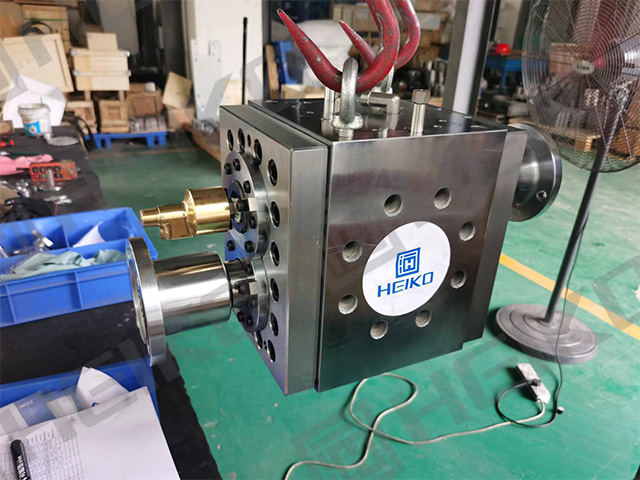

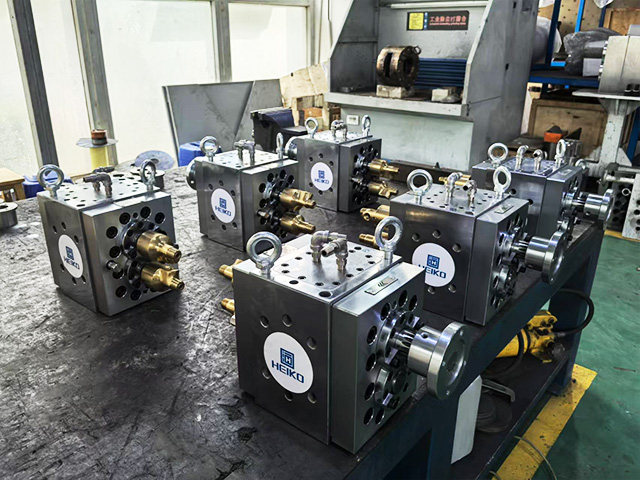

Wood-plastic composite melt pumps are widely used in wood-plastic profile production lines, such as in the extrusion process for producing skirting boards, door trims, door frame linings, louvers, picture frames, mirror frames, door frames, window frames, columns, stair railings, decorative panels, and furniture materials. In these production lines, the melt pump plays a role in stable melt conveying, precise metering, and pressure boosting, ensuring the dimensional accuracy and surface quality of the extruded products.

In summary, wood-plastic composite melt pumps are suitable for wood-plastic composites with various thermoplastic plastics and wood flour as the main raw materials, while appropriate amounts of plasticizers, light stabilizers, antibacterial agents, and powdered nitrile rubber are added to improve material properties. When selecting a melt pump, factors such as material viscosity, temperature stability, abrasion resistance, and corrosion resistance need to be considered.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Where are melt pumps for plastic sheet extruders used in the plastics industry?

Next:How to Calculate the Rotational Speed of a Melt Gear Pump