Role and Features of Batt Melt Pumps for Thermoplastic Extrusion

In thermoplastic extrusion processes, melt pumps are critical equipment installed between the extruder and the die. Their core function is to provide stable melt pressure and flow control through precise mechanical transmission. Below is a detailed analysis of their roles and features:

I. Primary Functions

Stable Extrusion Pressure and Flow

Traditional screw extruders rely on screw speed for pressure, which is susceptible to material fluctuations and temperature changes, causing instability. Melt pumps use meshing gears or screws to deliver melt at a constant displacement, significantly reducing pressure fluctuations. Ideal for high-precision products (e.g., films, optical fibers, medical tubing).

Enhanced Extrusion Efficiency and Output

Melt pumps enable independent control of pressure and flow, allowing extrusion at higher pressures and increasing production speeds. For high-viscosity materials (e.g., PC, PEEK), pumps transfer torque more efficiently, preventing screw slippage.

Improved Product Quality

Stable pressure and uniform melt flow reduce defects (e.g., uneven thickness, sharkskin texture), enhancing surface finish and dimensional accuracy.

Optimized Temperature Control

Compact pump designs shorten melt residence time, reducing degradation risks from high temperatures.

II. Core Features

High-Precision Metering

Gear-based volumetric delivery ensures displacement errors <±1%, suitable for applications requiring strict material ratios (e.g., multi-layer co-extrusion).

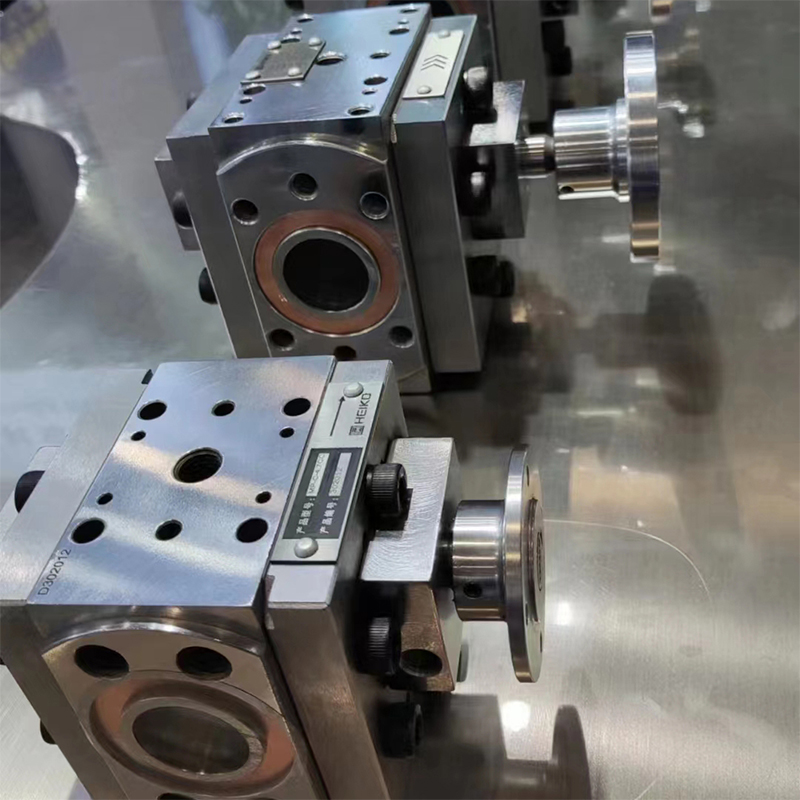

High-Pressure and High-Viscosity Resistance

Constructed with wear/corrosion-resistant materials (e.g., nitrided steel, tungsten carbide coatings) to withstand up to 40MPa pressure, ideal for processing high-viscosity engineering plastics (e.g., LCP, PPS).

Self-Cleaning and Low Maintenance

Optimized flow channels minimize dead zones, preventing melt degradation; modular designs allow quick disassembly for cleaning.

Flexible Adaptability

Integrates with single/twin-screw extruders, supporting various screw diameters and speeds to meet diverse process needs.

Energy Efficiency and Noise Reduction

Stable pressure reduces energy waste, lowering consumption by ~15-20% compared to screw-only systems; precision machining minimizes operational noise.

III. Typical Applications

High-Precision Products: Optical films, capacitor films, lithium-ion battery separators.

High-Viscosity Materials: PVC profiles, engineering plastic pipes.

Multi-Layer Co-Extrusion: Composite packaging films, cable jackets.

Reactive Extrusion: Polymerization reactions requiring precise residence time control.

IV. Key Selection Parameters

Displacement Range: Select based on target output (e.g., 0.1-12,000 cm³/rev).

Pressure Rating: Match die resistance (e.g., 10-30MPa for films, 20-50MPa for pipes).

Viscosity Compatibility: High-viscosity materials require large tooth gaps or specialized screw designs.

Material Compatibility: Select pump materials based on plastic properties (e.g., fluoropolymers, Hastelloy).

Properly configured melt pumps significantly enhance extrusion line stability, efficiency, and product quality, making them indispensable in high-end applications.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Zhengzhou Heiko Invites You to Visit Booth 8B61 at CHINAPLAS 2025

Next:Production process applicable to melt pumps