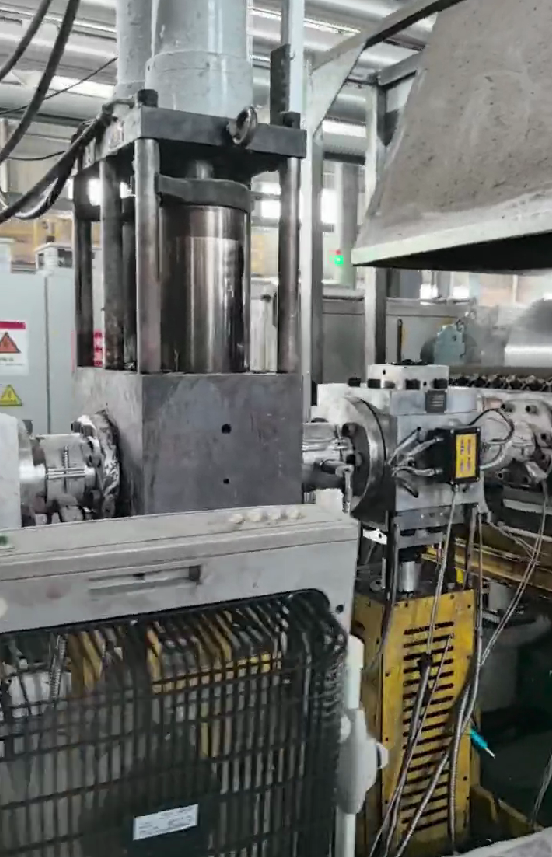

double-column screen changers in the PE battery separator industry

The application of double-column screen changers in the PE battery separator industry is mainly embodied in the following aspects:

I. Ensuring Continuity and Stability of the Production Process

Continuous Impurity Filtration: During the production of PE battery separators, impurities may exist in the raw material melt, which can affect the performance and quality of the separators. The double-column screen changer, with its special filter screen design, can continuously filter out impurities from the melt, ensuring the continuity of the production process and the purity of the product.

Non-stop Screen Change: The double-column screen changer for PE extruder employs an alternating mode of one screen working while the other is being replaced, allowing for screen replacement without stopping the production line. This eliminates production interruptions caused by downtime for screen changes, ensuring the continuity of production.

II. Improving Production Efficiency and Product Quality

Enhanced Production Efficiency: As the screen change process does not require downtime, the double-column screen changer significantly improves the production efficiency of PE battery separators, reducing production cycles and costs.

Improved Product Quality: By effectively filtering impurities from the melt, the double-column screen changer enhances the quality of PE battery separators, minimizing performance degradation and defects caused by impurities.

III. Meeting the Specific Needs of the PE Battery Separator Industry

High Pressure and Temperature Resistance: During the production of PE battery separators, the melt may be subjected to high temperatures and pressures. The double-column screen changer, with its excellent high-pressure and high-temperature resistance, is able to meet these specific requirements.

Optimized Feed and Venting Structures: By optimizing the feed and venting structures, the double-column screen changer reduces pressure fluctuations during screen changes, ensuring the continuity and stability of production. This is particularly important for PE battery separators, which have high requirements for quality stability.

IV. High Automation Level, Reduced Labor Intensity

Automated Operation: The double-column screen changer is typically equipped with an advanced automation control system that enables automatic alarm and control functions, reducing the frequency and labor intensity of screen change operations for workers.

V. Prolonged Equipment Lifespan

High-quality Materials: The hydraulic continuous screen changer is made from high-quality materials such as alloy steel and undergoes processes like nitriding treatment, which can extend the equipment's lifespan and reduce maintenance and replacement costs.

In summary, the double pillar screen changer has extensive application value in the PE battery separator industry, ensuring continuity and stability of the production process, improving production efficiency and product quality, reducing labor intensity, and prolonging equipment lifespan.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:What is the speed range of the melt pump?

Next:Function and characteristics of extruder melt pump