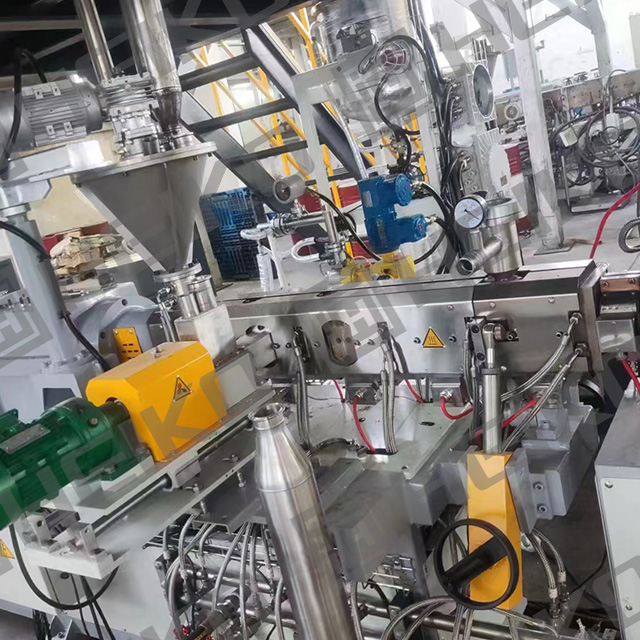

The use of melt pump in the granulation of fluoroplastic (PTFE FEP PFA) strips

The use of extruder melt pumps in the strand granulation of fluoroplastics (such as PTFE, FEP, and PFA) is of great significance, mainly reflected in the following aspects:

Ensuring Melt Homogenization and Stable Transportation

During the strand granulation process of fluoroplastics, melt pumps can ensure further homogenization of the melt, resulting in a pulse-free material output with stable pressure. This helps improve product quality, ensuring that the extruded fluoroplastic strips have uniform dimensions and consistent performance. Given the high-temperature stability, corrosion resistance, and other characteristics of fluoroplastics, the stable transportation capability of melt pumps is crucial for ensuring the realization of these properties.

Improving Production Efficiency and Reducing Energy Consumption

Melt pumps are designed with efficient designs and materials, capable of reducing energy consumption and enhancing transportation efficiency. During the strand granulation process of fluoroplastics, the stable transportation capability of melt pumps allows the production line to operate efficiently, reducing downtime and maintenance frequency, thereby improving production efficiency. Additionally, melt pumps can transfer the pressure reduction function of the extruder to the gear pump, enabling the extruder to operate at low pressure and temperature, further reducing energy consumption.

Precise Control of Temperature and Pressure

In the strand granulation process of fluoroplastics, the control of temperature and pressure is crucial for product quality and stability. Melt pumps can accurately control the temperature and pressure of raw materials, ensuring stability and uniformity during transportation and mixing. This precise control of temperature and pressure helps reduce fluctuations and abnormalities during the production process, improving product qualification rates and stability.

Simplifying the Production Process

In fluoroplastic strand granulation production lines, melt pumps can be used in conjunction with single-screw or twin-screw extruders, eliminating the granulation process and directly extruding products. This not only simplifies the production process but also enhances production efficiency. Additionally, the use of melt pumps can eliminate feeding errors in the feeding system, significantly reducing fluctuations transmitted from upstream processes, allowing the production line to reach a stable operating state faster.

In summary, the use of melt pumps in the strand granulation of fluoroplastics offers numerous advantages, including ensuring melt homogenization and stable transportation, improving production efficiency and reducing energy consumption, precise control of temperature and pressure, and simplifying the production process. At the same time, attention should be paid to inspection and installation, preheating and startup, loading and adjustment, monitoring and maintenance during use.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:What is the impact of the measurement accuracy of the melt pump on material quality

Next:Pipe extrusion melt pump