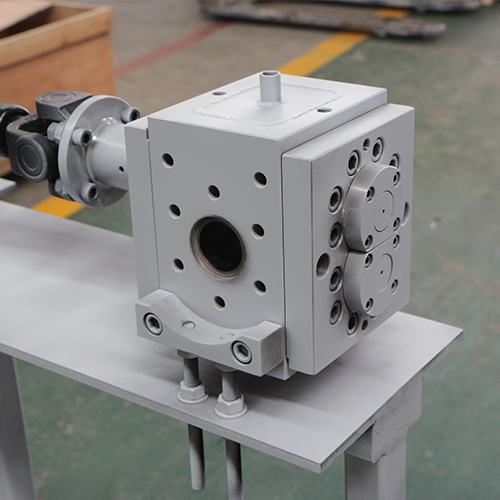

TPU Granulation Melt Pump

The TPU Granulation Melt Pump is a device specifically designed for the conveying, pressurization, and metering of high-temperature, high-viscosity polymer melts in TPU (thermoplastic polyurethane elastomer) granulation production lines. Below is a detailed introduction to the TPU Granulation Melt Pump:

I. Working Principle

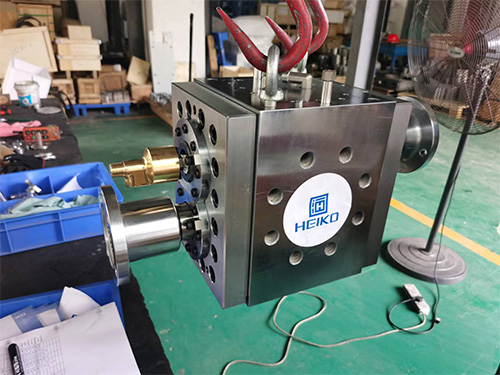

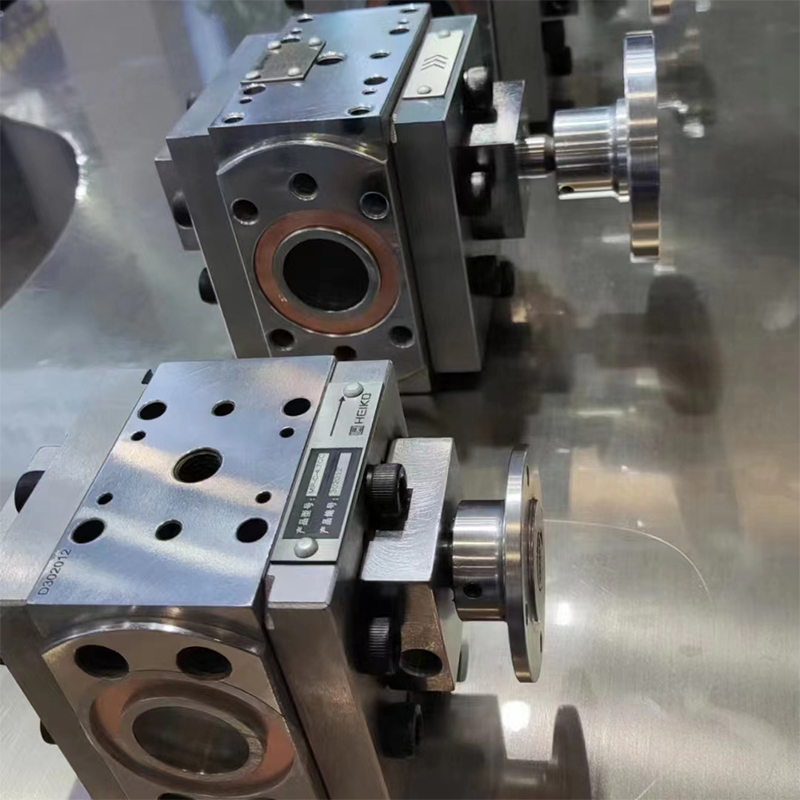

The TPU Granulation Melt Pump is a positive displacement conveying device, with its flow rate strictly proportional to the pump's rotational speed. It mainly consists of a pump casing, driving gear, driven gear, sliding bearings, front and rear end plates, gland seals, etc. During operation, the change in working volume caused by the meshing of the driving and driven gears is used to convey the melt. When the gears rotate in the specified direction, the melt enters the tooth spaces of the two gears in the feed area. As the gears rotate, the melt is brought into the conveying area from both sides. The re-meshing of the gears extrudes the melt in the tooth spaces and pushes it out into the discharge area, where it is pressed and conveyed to the outlet piping.

II. Technical Characteristics

High Pressure and High Viscosity: The TPU Granulation Melt Pump can be applied to high-pressure (e.g., 40MPa) and high-viscosity (e.g., 40,000Pa•s) conditions, suitable for conveying and pressurizing TPU and other high-temperature, high-viscosity polymers.

Precise Metering: The melt pump has precise metering capabilities, ensuring stable and accurate delivery of the melt to the extruder die, thereby improving the dimensional accuracy of extruded products and reducing waste rates.

Efficient Self-Cleaning: The TPU Melt Pump features a precise structure and smooth flow channels, providing efficient self-cleaning capabilities with no residual material or dead corners, avoiding material retention and degradation within the pump body.

Accurate Temperature Control: Pressure sensor holes and temperature sensor holes are provided on both the pump body and exterior, facilitating precise control of the melt's temperature and pressure, ensuring stability and reliability in the production process.

III. Application Fields

The TPU Granulation Melt Pump is widely used in extrusion systems for TPU elastomers and easily degradable plastics, such as polybutadiene rubber, chloroprene rubber, EPDM, SBR, EVA, natural rubber, and other processes. Additionally, it can be used in series with other types of extruders (e.g., single-screw or co-rotating twin-screw extruders) to improve the efficiency and product quality of the entire production line.

IV. Operation and Maintenance

Startup and Operation: When starting the TPU Granulation Melt Pump, it should first be operated at low speed. Once the pump operates stably, gradually adjust to the normal rotational speed and pressure. If the pump rotates unevenly, it must be stopped to check the cause to prevent severe internal damage to the pump.

Maintenance and Servicing: Regular maintenance and servicing of the pump are crucial for ensuring its long-term stable operation. This includes cleaning the pump body, replacing seals, and checking gear wear. When dismantling and cleaning the pump body, handle with care to avoid damaging the pump body and components.

Safety Precautions: When operating the TPU Granulation Melt Pump, strictly adhere to safety operating procedures to ensure the safety of personnel and equipment. In case of abnormalities or malfunctions, immediately stop the machine and seek help from professionals.

In summary, the TPU Granulation Melt Gear Pump is an indispensable device in TPU granulation production lines, featuring high pressure and high viscosity, precise metering, efficient self-cleaning, and accurate temperature control. Through reasonable use and maintenance, the long-term stable operation and efficient production of the TPU Granulation Melt Pump can be ensured.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:The screen changer for PP modified plastic granulation

Next:What is the impact of the measurement accuracy of the melt pump on material quality