Revolutionizing Rubber Processing with the New Rubber Extrusion Gear Pump

Industry Innovation Unveils Groundbreaking Equipment for Enhanced Efficiency and Precision

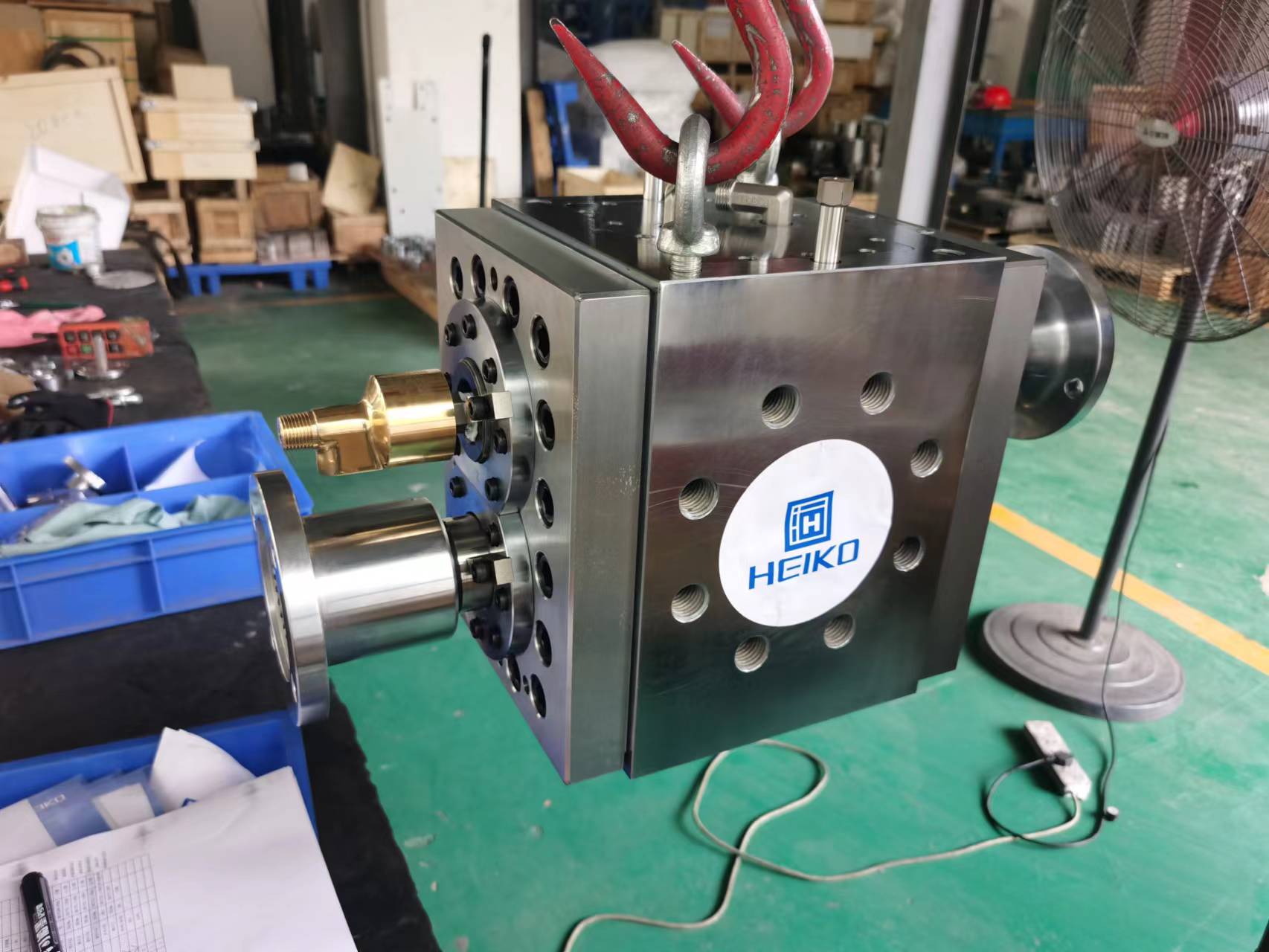

In a significant leap forward for the rubber processing industry, a cutting-edge Rubber Extrusion Melt Gear Pump has been introduced to the market. This state-of-the-art equipment promises to revolutionize rubber extrusion processes by delivering unprecedented levels of efficiency, precision, and reliability.

A Game-Changer for Rubber Manufacturers

The Rubber Extrusion Gear Pump represents a major breakthrough in technology, designed specifically to meet the growing demands of rubber manufacturers for high-quality, consistent outputs. Traditional extrusion methods often struggle with maintaining consistent pressure and flow rates, leading to inconsistencies in the final product. However, this innovative gear pump addresses these challenges head-on.

Key Features and Benefits

Enhanced Pressure and Flow Control: The gear pump's precision-engineered gears provide exceptional pressure and flow control, ensuring a consistent and stable extrusion process. This results in uniform rubber profiles with minimal waste and rework.

Improved Material Handling: The pump is capable of handling a wide range of rubber formulations, from soft to hard compounds, with ease. Its robust design ensures that even the most viscous materials can be processed smoothly and efficiently.

Energy Efficiency: By reducing the need for excessive pressure and temperature adjustments during extrusion, the gear pump contributes to significant energy savings. This not only lowers operational costs but also aligns with the industry's growing emphasis on sustainability and environmental responsibility.

Longevity and Reliability: Constructed from high-quality materials and precision-machined components, the Rubber Extrusion Gear Pump is built to last. Its durable design ensures minimal downtime and maintenance requirements, maximizing productivity and profitability.

Versatility in Applications: Whether used in automotive parts manufacturing, construction material production, or any other rubber-related industry, the gear pump offers versatile performance. Its ability to adapt to different extrusion processes and materials makes it an invaluable asset for a wide range of applications.

Industry Reaction and Expert Opinions

Industry experts have hailed the Rubber Extrusion Gear Pump as a game-changer. "This innovative equipment marks a significant step forward in the evolution of rubber processing technology," said Dr. John Smith, a renowned rubber scientist. "Its ability to provide consistent and reliable extrusion performance will undoubtedly set new standards in the industry."

Manufacturers have also expressed enthusiasm for the new gear pump. "We were looking for a way to improve our extrusion processes and reduce waste, and this gear pump has delivered on all fronts," said Jane Doe, production manager at a leading rubber products company. "The increase in efficiency and product quality has been remarkable."

As the rubber processing industry continues to evolve, the Rubber Extrusion Gear Pump stands out as a pioneering solution. Its combination of advanced technology, precision engineering, and sustainability makes it an essential tool for manufacturers striving to stay ahead of the competition.

With its impressive array of features and benefits, the Rubber Extrusion Gear Pump is poised to become the industry standard for rubber extrusion processes. Manufacturers who adopt this innovative equipment will undoubtedly experience a transformative impact on their production efficiency, product quality, and overall profitability.

Stay tuned for more updates on this groundbreaking product and its continued contributions to the rubber processing industry.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Exploring Melt Pumps: A Legendary Application Across Rubber, Chemical Fiber, and Pipeline Chemicals

Next:Application of Screen Changer in Plastic Recycling Processing for Extruders