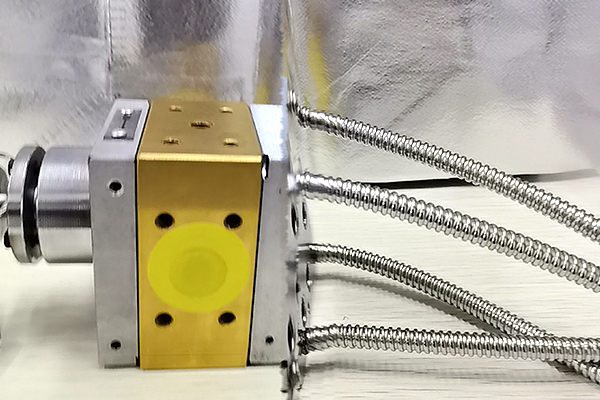

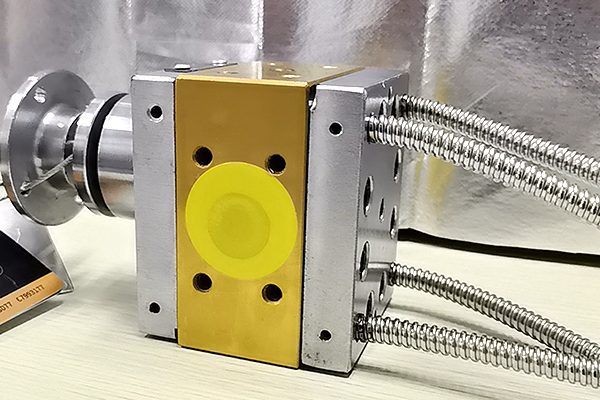

Laboratory Melt Metering Pumps: Application Areas and Performance Advantages

Application areas of laboratory melt metering pumps

Plastic processing: in plastic extrusion, blow molding, injection molding and other experiments, accurate metering and delivery of high-viscosity plastic melt, such as polyolefins, engineering plastics.

Rubber research: used for rubber mixing rubber delivery, help rubber formula research and development and performance testing.

Chemical fiber production experiments: stable conveying of chemical fiber melts, to support the development of new fiber materials.

Colleges and universities and scientific research institutions: as the basic experimental equipment in the field of material processing, it meets the research needs of scientific researchers on material conveying and processing.

Second, the laboratory melt metering pump features

High-precision metering: the melt metering pump can accurately control the melt flow to ensure the accuracy and repeatability of the experimental data.

Stable flow: it can provide stable melt delivery and reduce the impact of flow fluctuations on experimental results.

Miniaturized design: compact size, suitable for the environment of limited laboratory space, easy to install and operate.

Resistant to high viscosity: can handle high viscosity melt materials, adapt to the experimental needs of different materials.

Various materials: the pump body and parts of the melt metering pump are made of a variety of corrosion-resistant and wear-resistant materials, which prolongs the service life and adapts to materials with different chemical properties.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Core functions and advantages of manual quick screen changer

Next:Exploring Melt Pumps: A Legendary Application Across Rubber, Chemical Fiber, and Pipeline Chemicals