Plastic Sheet Extrusion Melt Pump

The melt gear pump for plastic sheet extrusion is a crucial piece of equipment in polymer material processing. Below is a detailed introduction to it:

I. Basic Structure

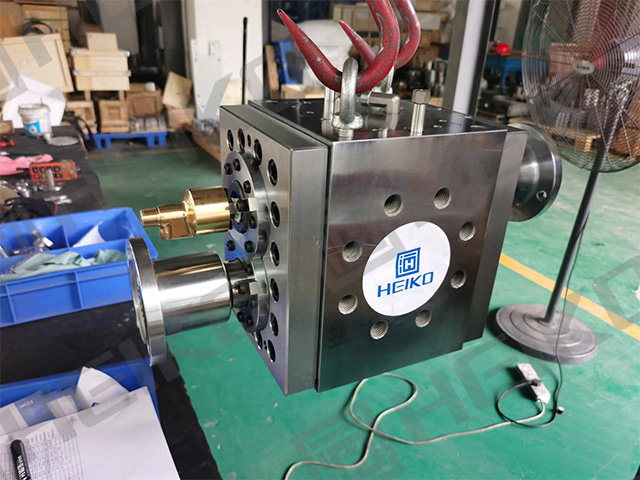

The melt pump for plastic sheet extrusion is mainly composed of key components such as the pump casing, driving gear, driven gear, sliding bearing, front and rear end plates, and gland packing seal. These components work in precise coordination, forming the foundation for the efficient operation of the melt pump.

Pump Casing: Serving as the supporting framework of the entire pump, it not only protects the internal gears from external environmental influences but also ensures a smooth flow path for the melt within the pump.

Driving Gear and Driven Gear: Precisely meshed, they are the core power source for conveying the melt in the melt pump.

Sliding Bearing: It supports the gears and reduces friction, ensuring stability and durability during high-speed rotation.

Front and Rear End Plates and Gland Packing Seal: Together, they constitute the sealing system of the pump body, preventing melt leakage and ensuring stable pressure within the pump.

II. Working Principle

The working principle of the melt pump is based on the change in working volume caused by the mutual meshing of the driving and driven gears to convey the melt. When the gears rotate in the specified direction, the melt first enters the feed area formed by the tooth profiles of the two gears, the pump body, and the side cover plate. In this area, the melt is effectively introduced into the tooth spaces of the two gears. As the gears continue to rotate, the melt in the tooth spaces is gradually brought into the conveying area. During this process, the melt is squeezed and pushed by the gears, flowing forward along the internal channels of the pump body. When the gears continue to rotate until they mesh again, the melt in the tooth spaces is further squeezed and extruded into the discharge area, ultimately being sent through the outlet pipeline to the downstream extruder die or mold.

III. Performance Parameters

The performance parameters of the melt pump for plastic sheet extrusion typically include the viscosity of the conveyed medium, suction pressure, discharge pressure, pressure difference, and operating temperature.

Viscosity of Conveyed Medium: 140,000 Pa·s (140,000,000 cP).

Suction Pressure: Vacuum (-0.00 to -0.03 MPa) to 30 MPa.

Discharge Pressure: 0 to 40 MPa.

Pressure Difference: ≤325 MPa.

Operating Temperature: ≤350 ℃.

IV. Functions and Advantages

Continuous and Stable Conveyance: The melt pump can continuously and stably convey the melt, ensuring the quality and production volume of extruded products.

Reduced Energy Consumption and Production Costs: By precisely controlling the conveyance volume of the melt, the melt pump helps reduce energy consumption and production costs.

Extended Machine Lifespan: The precise design and stable performance of the melt pump contribute to extending the lifespan of the entire extrusion production line.

V. Application Fields

Melt pumps are widely used in sheet extrusion lines for polymers such as plastics, resins, and rubbers. They have important applications in various fields, including chemical fibers, granulation, plastic films, sheets, plates, profiles, pipes, and more.

In summary, the melt pump for plastic sheet extrusion plays a vital role in the polymer material processing industry. By deeply understanding and applying the working principles and technical characteristics of the melt pump, we can better leverage its important role in the field of polymer material processing and promote the sustained and healthy development of the industry.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Rubber Elastomer Melt Gear Pump

Next:What are the other application areas of melt pumps in the plastics processing industry?