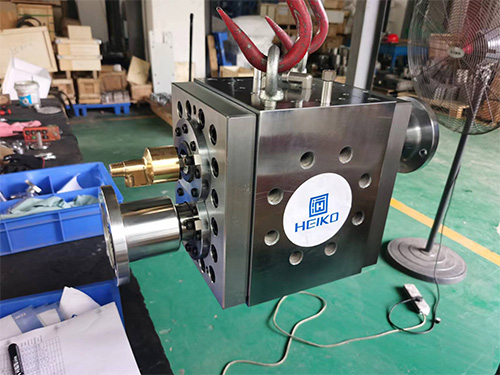

Rubber Elastomer Melt Gear Pump

The rubber elastomer melt gear pump is a specialized equipment designed for conveying and pressurizing rubber elastomer melts. Below is a detailed introduction to this pump:

I. Structural Characteristics

Pump Body: Made of high-temperature tool steel or chromium-nickel alloy steel to ensure sufficient strength and corrosion resistance in high-temperature and high-pressure environments.

Gears: The core components of the pump, made of high-temperature tool steel or nitrided steel, featuring high precision and wear resistance. The meshing clearance and tooth profile design of the gears have a significant impact on the pump's conveying efficiency and pressure stability.

Sliding Bearings: Made of high-temperature tool steel or other special materials and coatings, with excellent wear resistance and lubrication performance, ensuring the stability and reliability of the gears during operation.

Shaft Seals: Typically adopting spiral external drainage or other efficient sealing structures to prevent melt leakage and external air from entering the pump body.

II. Working Principle

The working principle of the rubber elastomer melt gear pump relies on the volume change and movement formed between the pump housing and the meshing gears to convey the liquid or pressurize it. When the pump starts, the driving gear shaft rotates along with the motor reducer, driving the driven shaft to rotate. On the suction side of the pump, the meshing teeth gradually separate, increasing the suction chamber volume and reducing the pressure, allowing the melt to enter the pump body. As the gears rotate, the melt entering the tooth grooves between the two gears is brought to the discharge chamber. The continuous meshing of the two gears extrudes the melt, and the discharge chamber pressurizes it into the pipeline behind the pump, thus completing the melt conveyance. This process is continuous, with the continuous rotation of the gears enabling continuous conveyance and pressurization of the melt.

III. Performance Characteristics

High-Precision Metering: The rubber elastomer melt gear pump can accurately control the conveying volume of rubber melts with minimal error, providing reliable support for standardized production of rubber products.

Precise and Rapid Temperature Control: Built-in cooling channels enable more precise and rapid temperature control, effectively improving the stability of product quality.

Special Lubrication Channel Design: Specifically designed lubrication channels for rubber and elastomer materials ensure that the gears operate normally in high-viscosity and somewhat corrosive rubber melt environments, reducing wear and extending the service life of the gear pump.

Optimized Flow Channels Reduce Residue: Through optimized design of the flow channels, dead corners within the flow channels are eliminated, effectively reducing polymer residue and improving product purity and quality stability.

Stable Output Pressure: Improved gear parameter design enables the gear pump to have a more precise displacement, capable of outputting stable pressure, ensuring the shape, dimensional accuracy, and physical properties of rubber products.

IV. Application Areas

The rubber elastomer melt gear pump is widely used in the production of rubber and elastomer products, such as tires, seals, and vibration-damping rubber parts. It can accurately meter and stably convey rubber melts, ensuring product quality and production efficiency. Additionally, this pump is suitable for other applications requiring high temperature and pressure, high sealing performance, and long service life, such as plastic processing, chemicals, pharmaceuticals, and the food industry.

In summary, the rubber elastomer melt gear pump features a compact structure, simple working principle, and stable and reliable performance, playing a crucial role in the production of rubber and elastomer products. During use, attention should be paid to installation, loading, monitoring, and maintenance to ensure its normal operation and extend its service life.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Laboratory extruder melt pump

Next:Plastic Sheet Extrusion Melt Pump