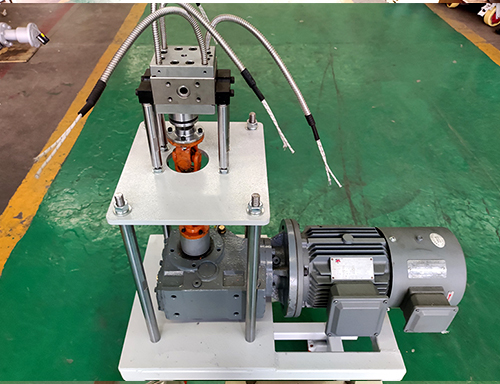

Laboratory extruder melt pump

The laboratory extruder melt pump is a precision fluid - conveying device used in laboratory environments. The following is its related introduction:

Function

It accurately measures and stably conveys high - temperature and high - viscosity polymer melts, ensuring stable melt flow and pressure during the extrusion process, improving product quality and production efficiency, and reducing material waste.

Working Principle

Relying on the rotation of a pair of meshing gears, the tooth grooves suck in the melt from the feeding section, and as the gears rotate, the melt enters the conveying area and is finally discharged from the discharging area.

Structural Composition

It is mainly composed of a pump body, front and rear covers, meshing gears, bearings, seals, etc.

Types

Common types include melt gear pumps, high - temperature melt pumps, extruder metering pumps, etc.

Characteristics

Accurate metering: It can accurately control the melt flow rate and ensure the consistency of product quality.

Stable pressure: It can reduce production problems caused by pressure fluctuations.

Energy - saving and efficiency - improving: By controlling the conveying volume, it reduces material waste and improves production efficiency and output.

Improving melt quality: It makes the melt mix more evenly and reduces non - uniformity.

Suitable for high - viscosity: It is suitable for handling high - viscosity polymer melts.

Improving processing accuracy: It is conducive to accurately controlling the melt temperature and pressure.

Application Fields

It is widely used in the processing of polymer melts in industries such as plastics, chemicals, pharmaceuticals, and food.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Production process applicable to melt pumps

Next:Rubber Elastomer Melt Gear Pump