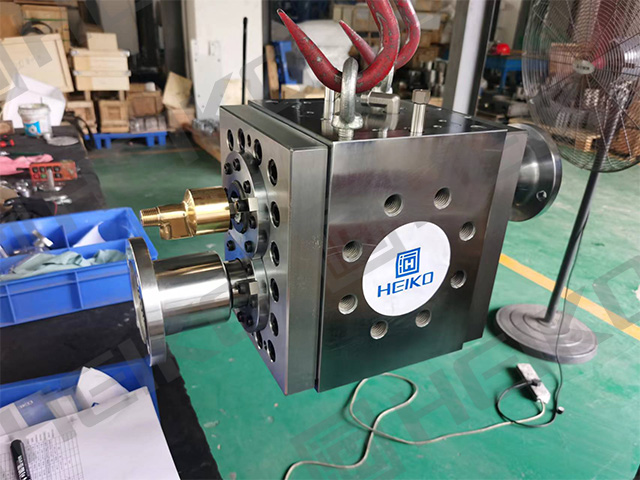

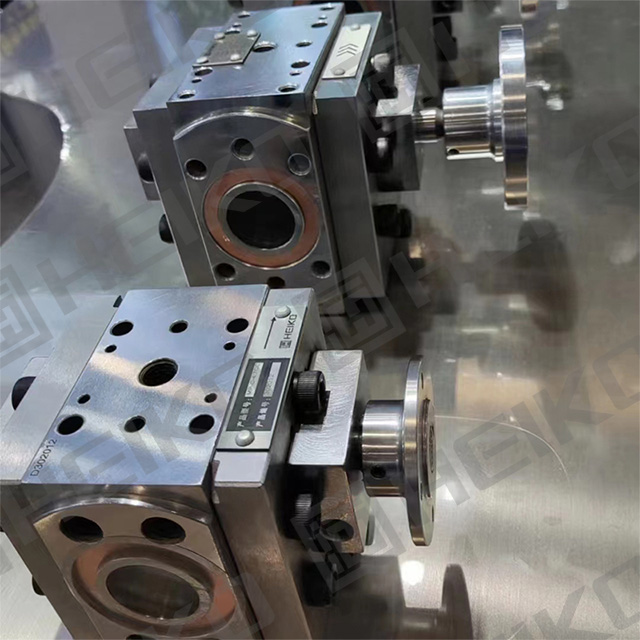

The Application Scope of Medical Tube Extrusion Melt Pumps

The application scope of medical tube extrusion melt pumps primarily focuses on the precise extrusion production of medical tubing. The detailed application scope is as follows:

I. Main Application Areas

Medical Tubing Production:

Medical tube extrusion melt pumps are widely used in the production of various medical tubing, such as infusion tubes, urinary catheters, respiratory tubes, etc. These tubing have extremely high requirements for dimensional accuracy and wall thickness uniformity. The melt pump can precisely control the flow rate and pressure of the polymer melt, ensuring that the tubing meets the precise dimensional requirements during the extrusion process.

II. Specific Application Scenarios

High-Precision Medical Tubing Production:

For some medical tubing with high-precision requirements, such as angiographic catheters, the melt pump can precisely control the flow rate of the melt, enabling the outer diameter tolerance of the catheter to be controlled within a very small range. This is crucial for accurately inserting the catheter into blood vessels during complex medical procedures and delivering medications or performing inspections.

Increasing Production Efficiency:

The melt pump can reduce the pressure requirements on the screw, allowing the screw to extrude at high speeds and efficiencies, thereby increasing production efficiency and output. In some medical tube extrusion lines, installing a melt pump can significantly increase production speed, meeting the growing market demand for medical tubing.

Optimizing Production Processes:

The melt pump can work in coordination with other equipment, such as extruders and molds, to make the entire production process smoother. By precisely metering and stably conveying the melt, it reduces the waste rate during production and lowers production costs.

Material Adaptability:

The melt pump can adapt to medical polymers with different viscosities and fluidities, such as thermoplastic elastomers (TPE) and polyvinyl chloride (PVC), ensuring versatility in the extrusion production of medical tubing with different materials.

III. Technical Features and Advantages

Stable Pressure and Flow Rate:

The melt pump can eliminate pressure fluctuations during the extrusion process, ensuring that the melt enters the mold at a stable pressure, thereby guaranteeing the stability and quality of the extruded medical tubing.

High-Precision Control:

The melt pump can precisely control the flow rate of the polymer melt, controlling the tube diameter tolerance within a very small range to meet the stringent dimensional requirements of medical tubing.

Long-Life Design:

Through optimized design and the selection of high-quality materials, the lifespan of medical tube extrusion melt pumps is usually long, reducing maintenance costs.

In summary, medical tube extrusion melt pumps play an important role in the precise extrusion production of medical tubing and have broad application prospects and market potential.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Plastic bottle extrusion melt pump

Next:What are the application areas of plastic extrusion melt pumps for wire and cable production?