Plastic bottle extrusion melt pump

The plastic bottle extrusion melt pump is a crucial device in the plastic extrusion molding process for conveying high-temperature molten plastic materials. Below is a detailed introduction to the plastic bottle extrusion melt pump:

I. Working Principle

The working principle of the plastic bottle extrusion melt pump involves using a rotating rotor to suction molten plastic material into the pump cavity, and then conveying the material towards the outlet end through the gap between the stator and the rotor. During the conveying process, the melt pump maintains the material in a molten state and ensures its uniformity and stability through pressure and temperature control.

Specifically, the melt pump is usually composed of two gears enclosed in a tightly fitting housing and driven by a motor. When the gears rotate, they meter precise amounts of material on the discharge side and achieve stability and efficiency in the extrusion process by precisely controlling the output volume of the molten material.

II. Functions and Advantages

Precise Control of Output Volume: The melt pump can precisely control the amount of material outputted to the die, eliminating many variables that affect the stability of extruder output, such as temperature fluctuations and feed interruptions.

Pressure Increase and Temperature Reduction: As a pressure-increasing device more effective than the extruder screw, the melt pump can reduce the die head pressure on the screw, thereby lowering the melt temperature and increasing the screw's output.

Mixing Effect: The melt pump also has a certain mixing effect, which helps improve the quality of the melt.

Enhanced Production Efficiency: By precisely controlling the output volume of the melt, the melt pump ensures the continuity and stability of the extrusion process, thereby increasing production efficiency.

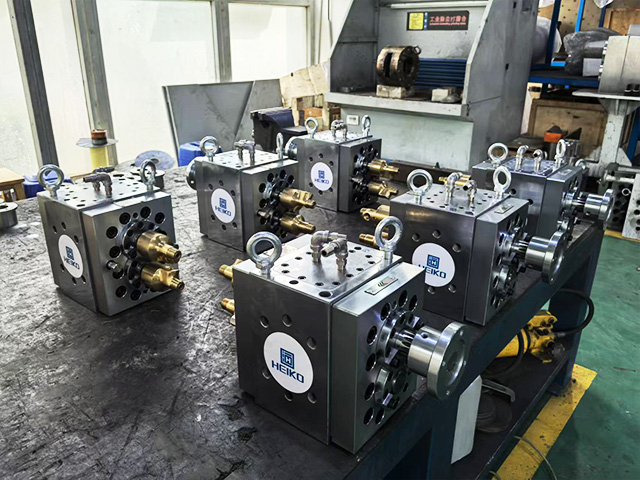

III. Structural Composition

The plastic bottle extrusion melt pump is mainly composed of parts such as the pump body, rotor, seals, bearings, and transmission device. These parts work together to ensure the efficient and stable operation of the melt pump.

IV. Installation and Commissioning

When installing the extruder melt pump, it needs to be placed on a flat surface to ensure the pump body's levelness and stability. At the same time, the inlet and outlet pipes need to be connected and properly sealed to prevent leakage and pressure loss. During the commissioning process, it is necessary to first check if the pump rotates flexibly and is free of sticking phenomena, and to ensure that the bearings and seals are well-lubricated. Then, adjust the pump's pressure and temperature parameters according to actual needs to meet production process requirements.

V. Operation and Maintenance

When using the plastic bottle extrusion melt pump, the following operational norms should be followed:

First, open the valves of the inlet and outlet pipes to ensure that molten plastic material can smoothly enter the pump cavity.

Observe the pump's operation. If abnormal sounds or vibrations are detected, stop the machine immediately to check and troubleshoot.

In daily maintenance, attention should be paid to the following points:

Regularly check the wear condition of seals and bearings, and replace worn parts in a timely manner.

Keep the pump body clean and well-lubricated.

Regularly clean the pump cavity and inlet and outlet pipes to prevent plugging and bonding.

In summary, the plastic bottle extrusion melt pump plays an important role in the plastic extrusion molding process. Through its advantages such as precise control of melt output, pressure increase and temperature reduction, mixing effect, and enhanced production efficiency, it helps ensure the stability and efficiency of the extrusion process. At the same time, certain specifications and precautions need to be followed in terms of installation, commissioning, operation, and maintenance to ensure the normal operation of the melt pump and extend its service life.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:Principle and explanation of melt pump

Next:The Application Scope of Medical Tube Extrusion Melt Pumps