Principle and explanation of melt pump

A melt pump is a device specifically designed for transporting, pressurizing, and measuring high-temperature and high viscosity polymer melts. The working principle and characteristics can be explained in detail as follows:

Working principle of melt pump:

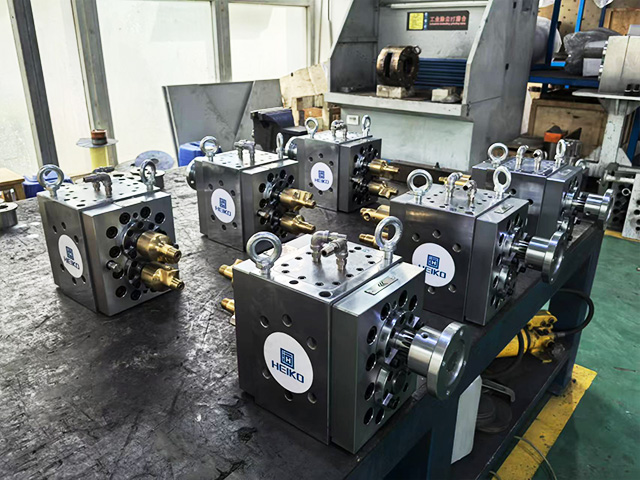

The melt pump is mainly composed of a pump body, front and rear side plates, two meshing gears, bearings, and seals. The tooth profile of the two gears, the pump body, and the side plate together constitute the feeding area, conveying area, and discharging area of the pump.

When the gear rotates in the specified direction, the melt will enter the tooth grooves of the two gears in the feeding area. As the gear rotates, the melt will be brought into the conveying area from both sides. When the gears mesh again, the molten material in the tooth groove will be squeezed out of the discharge area and pressed into the outlet pipe.

Due to the continuous rotation of the pump shaft, the gear will continuously push the melt towards the outlet side, so the pump outlet can reach a high pressure. For the imported flow rate and pressure, the melt pump does not have high requirements, and can even achieve vacuum suction.

Functions and characteristics of melt pump:

The main function of the melt pump is to pressurize and stabilize the high-temperature plastic melt from the extruder, and then steadily deliver the flow rate to the extruder head. Its ability to stabilize melt pressure and flow rate is superior to various types of extruders.

When used in series with a single screw or co rotating twin-screw extruder, the melt pump can significantly improve the efficiency of the entire production line. When the dimensional tolerance requirements for extruded products are strict or the raw material cost of the products is expensive, the use of a melt pump is more necessary and valuable.

The application of melt pumps can also reduce the energy consumption per kilogram of material processed, generally by about 25%.

Melt pumps are suitable for extrusion molding of plastic, resin, rubber products, such as granulation, film, pipe, sheet, and other industries. According to the tooth direction, it can be divided into straight teeth, helical teeth, herringbone teeth, etc.

Material and lubrication of melt pump:

Due to the continuous operation of the melt pump under high temperature and high pressure conditions, and the generally high viscosity and certain corrosiveness of the transported plastic melt, the material requirements for the melt pump are very high. Melt pumps are typically made of alloy tool steel, with gears and shafts integrated to ensure reliability under high torque conditions.

The lubrication and sealing issues of melt pumps are also quite complex. In order to prevent contamination of plastic melt, the melt pump cannot use general lubricating oil or grease for lubrication, but instead relies on the conveyed plastic melt for self lubrication. Therefore, the bearings and sealing structure of the melt pump must adapt to the special properties of plastic melt.

Email: sale@heikomachinery.com

WhatsApp: +86 13803717447

Previous:How to Select a Suitable PP Packing Strap Melt Pump?

Next:Plastic bottle extrusion melt pump